HDF- High Density Fiberboard (7 Product)

HDF - High Density Fiberboard is HDF plywood made of 80-85% of natural wood, the rest are additives, pressed under temperatures higher than 840kg / m3 to increase hardness and adhesion for the wood. Currently our factory is producing HDF board with E1 standard, the expansion is less than 8% or 12%, this is the standard to ensure the wooden core has enough hardness, durability, and natural origin, no not good for your health.

Product specifications

HDF thickness 7-12 mm. Suitable for the production of parquet floors, staircase cladding panels or other applications requiring strong stability.

HDF 4-6 mm thickness. Suitable for the manufacture of industrial wood doors and other applications where necessary.

1, Laminate flooring

Thickness of 8mm or 12mm. Laminate flooring is used quite popular in society today, it is an alternative material for tiles, natural wood flooring ... by stable quality, diverse colors, reasonable prices. In which the main component of laminate flooring is HDF core.

Structure of laminate flooring consists of 4 main layers:

Layer 1. Coating or abrasive layer: Covered with plastic to increase the resistance to scratches on the wooden floor.

2nd layer. Decorative paper: Pattern on wooden floors with UV protection.

Grade 3. Core board: This is the thickest layer in pressed wood. The use of HDF high density fiberboard is a high density, strong and durable wood.

4th layer. Balancing layer: is the layer that prevents moisture. Keep the balance of the wooden board to prevent bending. As well as preventing moisture from concrete floors.

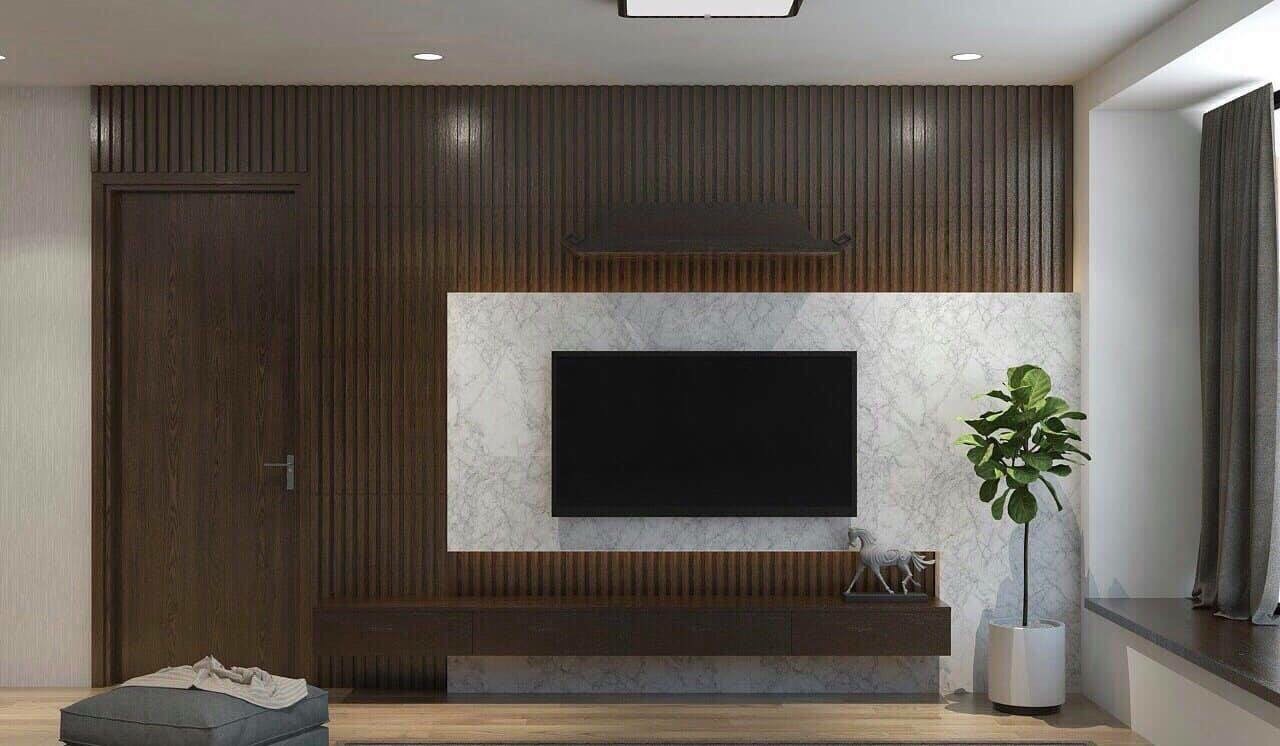

2, Industrial wood doors (Door) Thickness of HDF 4-6 mm.

Suitable for the production of industrial wood doors. It is a wood with high adhesion and not deformed to increase user convenience. The factory can also cut to size of the wood to fit the size the customer uses to make the door

3, Specification (Specification)